|

|

|

UV Reflectors

Reflectors Reflector

Beam Profiles Example

Application Order Now - Quote Request

| UV Reflector

Extrusions |

Aluminum reflectors are provided to assist

engineers to build a UV curing system without investing in extrusion

dies, long lead times, and minimum draw charges. These can be used

for low wattage applications in free air or forced air-cooling of UV

lamps in an end cooled reflector assembly, or center cooled reflector

assembly. These are commonly used for focusing uv light from a medium

pressure mercury vapor lamp, uv curing lamp or metal halide lamp as

metal halide reflectors.

Our extruded reflectors are made of specially processed 6061-grade aluminum. The inside surface is highly polished to yield an efficient transfer of UV energy from the uv bulb to the curing substrate. This high UV reflectance is approximately 90% and unlike other aluminum, this special grade resists tarnishing and corrosion. Enhanced reflectance liners, UV reflector liners or reflector sheets are not required; these products will typically only increase the uv reflectance, which is the amount of UV light from the ultraviolet lamp reaching the substrate by less than 5%.

Three styles are available, two elliptical and one parabolic diffuser.

Elliptical reflectors provide a line source. One focal

point is at the center of the UV lamps the other focal point is positioned

approximately 1.75" or

3.5" (depending

on reflector used) from the bottom edge of the reflector to, the substrate.

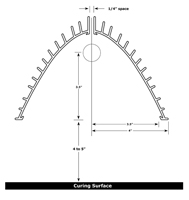

Parabolic aluminum reflector provide a collimated source and the reflectors

bottom edge should be located 4 to 5 inches from the substrate. Spherical

reflectors provide a non-uniform distribution of energy from UV lamps

and are not offered by Hill Technical. For proper lamp operation it

is important that each half of our reflectors is separated by approximately

one quarter of an inch to allow for convection cooling. |

E-175 |

E-350 |

|

|

1.75" Elliptical

10' Sections

|

3.5" Elliptical

12' Sections

|

PO-50 |

PO-70 |

|

|

5" Parabolic Diffuser

10' Sections

|

7" Parabolic Diffuser

10' Sections

Reflector is available

only with medium polish

|

Note when ordering!

Each aluminum reflector comes in 10-foot or 12-foot

sections. One section is only 1/2 of a reflector assembly, for example:

One 10-foot section is enough to build one 5-foot reflector

assembly. |

| Reflector Example Application |

| Below is an example of

how our UV reflectors can be mounted as part of an irradiator or Reflector

Assemblies in a finished UV Drying system. These systems use a magnetic

ballast or metal halide ballast to operate the uv curing lamp. It is

important to support the arc lamp positioned at the focal point of

the extruded reflectors. End plates can be fabricated out of plate

aluminum stock and screwed to the reflector. Because of the temperature

range that lamps achieve, they will physically expand and then contract

upon cooling. It is best to mount the ultravilolet lamp by constraining

it as little as possible. A simple way to accomplish this with UV lamps

is to make a "V" shaped

cut into a rectangular piece of aluminum. This plate can then be mounted

to the end plate. The lamp just rests in that "V" for

support. A similar concept can be applied for ultraviolet blood irradiation,

or other sterilization process such as water sterilizers or air sterilizer.

|

|

| |

Remember that lamp cooling is very important. Capillary temperature should be maintained at 250 to 350°C and quartz envelope should be maintained at 650 to 800°C. |

|

|

|

|

|

| |

Related UV reflectors include: UV reflectors, UV reflector, UV reflector extrusions, elliptical reflectors, reflector sheets, uv reflectance, Parabolic reflectors, Diffuser, end cooled reflector assembly, center cooled reflector assembly, E-175, E-350, PO-50, aluminum reflector, Aluminum reflectors, UV curing system, uv light, medium pressure mercury vapor lamp, metal halide lamp, metal halide reflectors, extruded reflectors, uv bulb, enhanced reflectance liners, parabolic diffuser, Parabolic aluminum reflector, curing system, magnetic ballast, metal halide ballast, uv curing lamp, arc lamp, ultravilolet lamp, ultraviolet lamp, UV Drying, irradiator, Reflector Assemblies, ultraviolet blood irradiation, sterilization, water sterilizers, air sterilizer, UV reflector liners, Dichroic reflectors, Hanovia UV end cooled reflector assembly, Hanovia, UV lamps

|

|