|

|

|

Heat Sinks

We specialize in Heat Sinks for medium to high-power

applications. We understand that designers are constantly being asked to

use more power in a smaller footprint at no additional cost. Our heat sink

designs are custom engineered to your specific needs. Our have experienced

thermal and mechanical engineers work with you to bring your designs from

concept to production. We use the latest thermal simulation software in

conjunction with highly sensitive thermal test equipment to provide accurate

data speeding your product to market. We specialize in Heat Sinks for medium to high-power

applications. We understand that designers are constantly being asked to

use more power in a smaller footprint at no additional cost. Our heat sink

designs are custom engineered to your specific needs. Our have experienced

thermal and mechanical engineers work with you to bring your designs from

concept to production. We use the latest thermal simulation software in

conjunction with highly sensitive thermal test equipment to provide accurate

data speeding your product to market. |

Bonded Fin Heat Sinks

Extruded Heat Sinks

Liquid Cooled Heat Sinks Heat Pipes

Value Added Assemblies

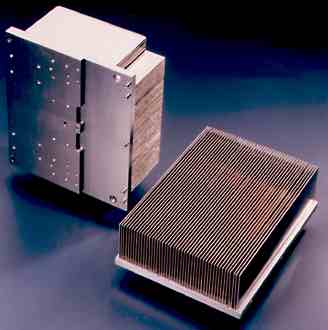

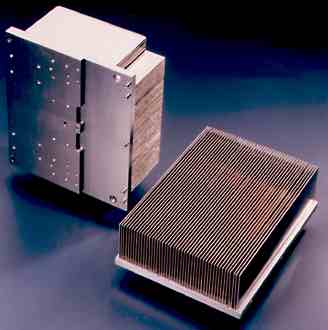

| Bonded Fin Heat Sinks |

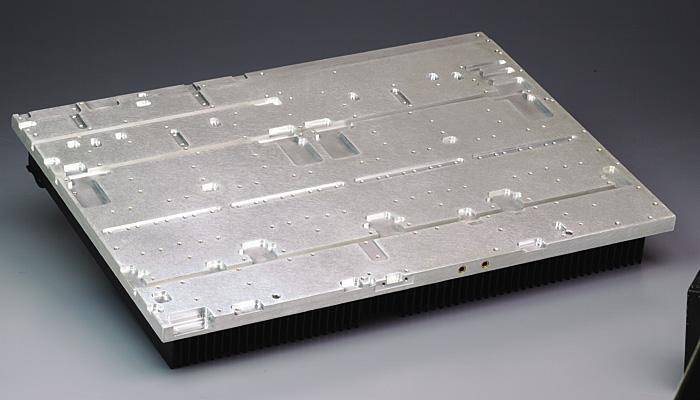

Bonded fin heat sinks allow a smaller package size

or lower thermal resistance than conventional aluminum extrusions in

forced air applications. We offer signal fin, and corrugated fin options

for our bonded fin heat sinks. Some versions of our corrugated fin stock

have an off set providing greater turbulence resulting in larger heat

transfer. It is normally possible to dissipate two to three times more

heat than conventional aluminum extrusions with our bonded fin designs.

In applications where space and high thermal density is a problem, copper

bonded versions are available. Copper has a thermal conductivity twice

that of aluminum. The fin density and fin height on both can be used

in countless combinations. We can provide you with the best possible

value, based on your unique application. Bonded fin heat sinks allow a smaller package size

or lower thermal resistance than conventional aluminum extrusions in

forced air applications. We offer signal fin, and corrugated fin options

for our bonded fin heat sinks. Some versions of our corrugated fin stock

have an off set providing greater turbulence resulting in larger heat

transfer. It is normally possible to dissipate two to three times more

heat than conventional aluminum extrusions with our bonded fin designs.

In applications where space and high thermal density is a problem, copper

bonded versions are available. Copper has a thermal conductivity twice

that of aluminum. The fin density and fin height on both can be used

in countless combinations. We can provide you with the best possible

value, based on your unique application. |

| Extruded Heat sinks |

| |

Extrusions used in a forced air system are the most

common heat sinking method. When compared to a natural convection

system substantially better performance can be realized. It is important

understand too that most "as purchased" extrusion heat sinks

are not sufficiently flat and require machining. Our heat sinks typically

come with a 0.001 per inch flatness and surface finish of 64 micro inches

over the area required. We are constantly working to improve our fin aspect

ratios and fin densities. We continually produce heat sink extrusions that

other manufacturers said "were not possible". For the finest in

extruded air-cooled heat sinks let us assist you with your extrusion design.

We will provide a cost effective solution for your cooling needs. Extrusions used in a forced air system are the most

common heat sinking method. When compared to a natural convection

system substantially better performance can be realized. It is important

understand too that most "as purchased" extrusion heat sinks

are not sufficiently flat and require machining. Our heat sinks typically

come with a 0.001 per inch flatness and surface finish of 64 micro inches

over the area required. We are constantly working to improve our fin aspect

ratios and fin densities. We continually produce heat sink extrusions that

other manufacturers said "were not possible". For the finest in

extruded air-cooled heat sinks let us assist you with your extrusion design.

We will provide a cost effective solution for your cooling needs. |

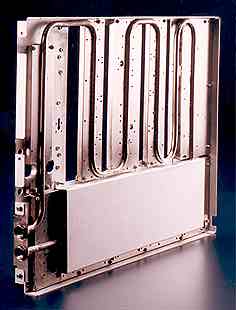

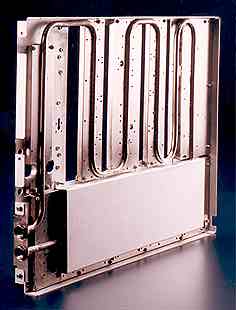

| Liquid Cooled Heat Sinks |

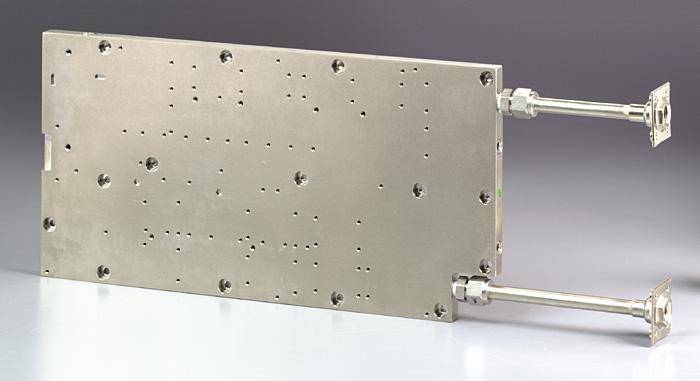

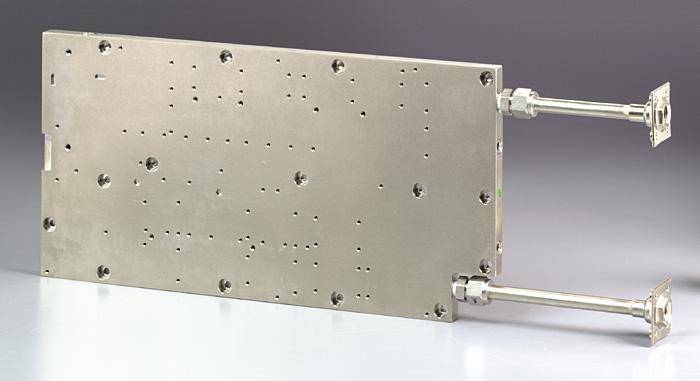

Liquid cooled heat sinks provide the highest thermal performance

per unit volume and when optimally designed can exhibit a very low thermal

resistance. Liquid heat sinks can be constructed by soldering copper tubing

on to a flat copper plate or by drilling holes in a metal block through

which water may pass. With greater complexity and greater thermal performance

an elaborate serpentine water channel may be milled in a copper or aluminum

block that later is sealed off. While liquid cooling may be considered

undesirable and /or unsatisfactory for many applications it may be the only

viable approach in specific situations. Liquid cooling, in addition to being

compact, keeps noise to a minimum and can increase semiconductor life due to

reduced temperatures. We can also provide chiller units for complete cooling systems. Liquid cooled heat sinks provide the highest thermal performance

per unit volume and when optimally designed can exhibit a very low thermal

resistance. Liquid heat sinks can be constructed by soldering copper tubing

on to a flat copper plate or by drilling holes in a metal block through

which water may pass. With greater complexity and greater thermal performance

an elaborate serpentine water channel may be milled in a copper or aluminum

block that later is sealed off. While liquid cooling may be considered

undesirable and /or unsatisfactory for many applications it may be the only

viable approach in specific situations. Liquid cooling, in addition to being

compact, keeps noise to a minimum and can increase semiconductor life due to

reduced temperatures. We can also provide chiller units for complete cooling systems.

We commonly use several cold plate construction methods:

Sizes of these plates range from a few centimeters to slightly more than 2 meters. |

| |

| Two Piece Gasket |

|

| Full Buried Tube |

|

| Deep Drilled |

|

| Two Piece Brazed |

|

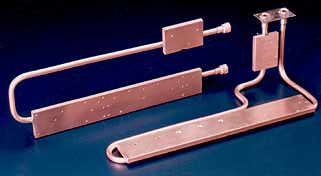

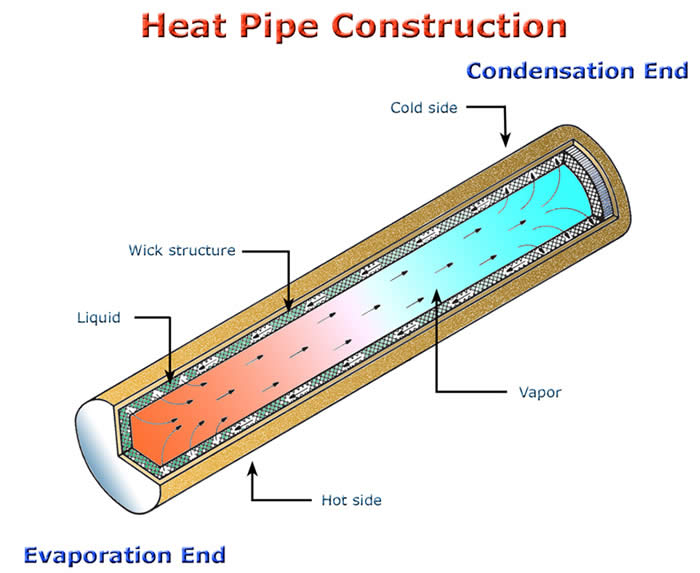

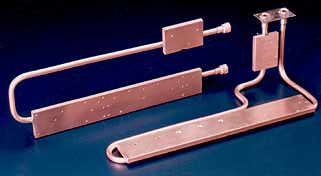

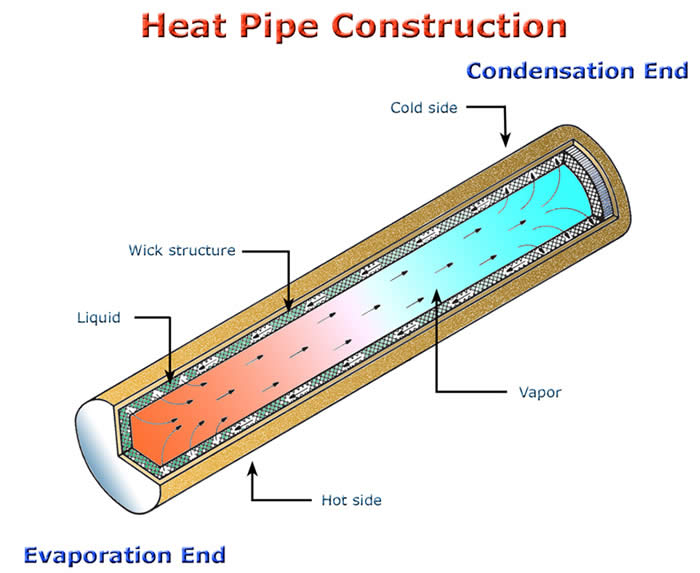

| Heat Pipes |

For maximum power heat transfer we offer Powder Type heat pipes. These come in standard lengths from 150 to 300 mm. Tube diameters range from 2 to 8 mm with maximum power capacity of 45 watts. For maximum power heat transfer we offer Powder Type heat pipes. These come in standard lengths from 150 to 300 mm. Tube diameters range from 2 to 8 mm with maximum power capacity of 45 watts.

Tubes can be flattened in order to stack several heat pipe into a very tight space in order to increase heat carrying capacity of an assembly. Heat pipes are typically supplies as a finished assembly integrated with a plate and fins (corrugated, or zipper fins are most common)

Advantage of Powder Type Heat Pipes

• The best for heat transfer.

• Better quality reliability.

• Workable for any operation direction

• Easy for bending and flatten.

Disadvantage

• Higher cost.

• Difficult to produce.

• Flattening limitation (2mm)

The above drawing depicts basic heat pipe construction and theory of operation.

In general a heat pipe consists of a sealed usually aluminum or copper tube, a wicking structure and a few cc’s of fluid under pressure. When heat is applied to a point along the length of the heat pipe the liquid at that point will boil into a vapor. By boiling, the liquid extracts heat through vaporization (turning into a gas). As a gas, this vapor travels to the cold side of the heat pipe and condenses back into a fluid. This fluid then moves back through the wicking structure and the process is repeated.

|

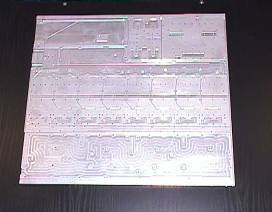

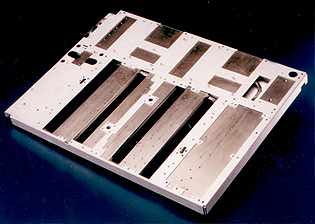

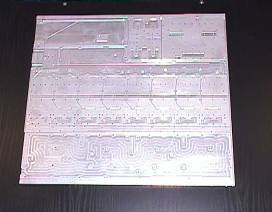

| Value Added Assemblies |

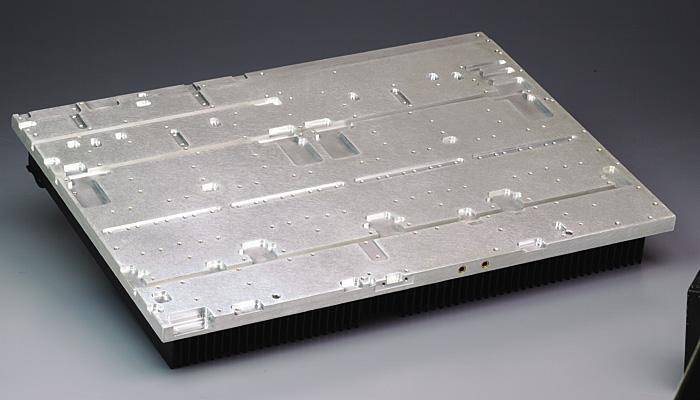

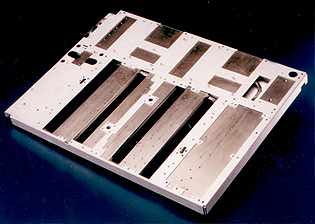

Typically it is advantageous to design a heat sink

assembly that can reduce waste created by additional handling through

secondary operations at your facility. We will work with you to design

an assembly which can drop right into your product, reducing handling

cost and potential damage. Items integrated into our heat sink assemblies

include, Shielding such as EMI/RFI barrier walls, Hardware like standoffs

and studs for mounting, Chassis and interface sheet metal. Also, we can

provide you with an extensive variety of finishes which include plating,

painting, and silk screening. We want to incorporate as much into the

assemblies as possible so that when you take our assembly to the factory

floor you can immediately interface it to the product for fast shipment

to your customer. We will work with you on mechanical components in order

to reduce your assembly time and inventory cost. Typically it is advantageous to design a heat sink

assembly that can reduce waste created by additional handling through

secondary operations at your facility. We will work with you to design

an assembly which can drop right into your product, reducing handling

cost and potential damage. Items integrated into our heat sink assemblies

include, Shielding such as EMI/RFI barrier walls, Hardware like standoffs

and studs for mounting, Chassis and interface sheet metal. Also, we can

provide you with an extensive variety of finishes which include plating,

painting, and silk screening. We want to incorporate as much into the

assemblies as possible so that when you take our assembly to the factory

floor you can immediately interface it to the product for fast shipment

to your customer. We will work with you on mechanical components in order

to reduce your assembly time and inventory cost. |

|

|

|

| |

Related heat sinks include: bonded fin heat sinks, extruded heat sinks, liquid cooled heat sinks, thermal management heat sinks, heat exchangers heat sinks, soldered fin heat sinks, extruded heat sink, folded fin heat sink, high power heat sink, cold plate heat sink, impingement cooling heat sink, convection cooling heat sink, forced air cooling heat sink, extrusions heat sink, corrugated fin heat sink, convoluted fin heat sink, bored fin heat sink, epoxy fin heat sink, bonding heat sink, epoxy bonded fin heat sink, high power thermal management heat sink, thermal management heat sink, natural convection heat sink, forced convection heat sink, metallurgical bonding heat sink, high power application heat sink, thermal packaging heat sink, thermal design heat sink, braised heat sinks, heat pipes, copper heat sinks, bonded fin air cooled heat sinks, extruded heatsinks, high fin density heat sink, liquid cooled chill blocks heat sink, igbts heatsink, igbt heat sink, aadvid heat sink, wakefield heat sink, thermalloy heat sink, r-theta heat sink

|

|

Bonded fin heat sinks allow a smaller package size

or lower thermal resistance than conventional aluminum extrusions in

forced air applications. We offer signal fin, and corrugated fin options

for our bonded fin heat sinks. Some versions of our corrugated fin stock

have an off set providing greater turbulence resulting in larger heat

transfer. It is normally possible to dissipate two to three times more

heat than conventional aluminum extrusions with our bonded fin designs.

In applications where space and high thermal density is a problem, copper

bonded versions are available. Copper has a thermal conductivity twice

that of aluminum. The fin density and fin height on both can be used

in countless combinations. We can provide you with the best possible

value, based on your unique application.

Bonded fin heat sinks allow a smaller package size

or lower thermal resistance than conventional aluminum extrusions in

forced air applications. We offer signal fin, and corrugated fin options

for our bonded fin heat sinks. Some versions of our corrugated fin stock

have an off set providing greater turbulence resulting in larger heat

transfer. It is normally possible to dissipate two to three times more

heat than conventional aluminum extrusions with our bonded fin designs.

In applications where space and high thermal density is a problem, copper

bonded versions are available. Copper has a thermal conductivity twice

that of aluminum. The fin density and fin height on both can be used

in countless combinations. We can provide you with the best possible

value, based on your unique application. Extrusions used in a forced air system are the most

common heat sinking method. When compared to a natural convection

system substantially better performance can be realized. It is important

understand too that most "as purchased" extrusion heat sinks

are not sufficiently flat and require machining. Our heat sinks typically

come with a 0.001 per inch flatness and surface finish of 64 micro inches

over the area required. We are constantly working to improve our fin aspect

ratios and fin densities. We continually produce heat sink extrusions that

other manufacturers said "were not possible". For the finest in

extruded air-cooled heat sinks let us assist you with your extrusion design.

We will provide a cost effective solution for your cooling needs.

Extrusions used in a forced air system are the most

common heat sinking method. When compared to a natural convection

system substantially better performance can be realized. It is important

understand too that most "as purchased" extrusion heat sinks

are not sufficiently flat and require machining. Our heat sinks typically

come with a 0.001 per inch flatness and surface finish of 64 micro inches

over the area required. We are constantly working to improve our fin aspect

ratios and fin densities. We continually produce heat sink extrusions that

other manufacturers said "were not possible". For the finest in

extruded air-cooled heat sinks let us assist you with your extrusion design.

We will provide a cost effective solution for your cooling needs. Liquid cooled heat sinks provide the highest thermal performance

per unit volume and when optimally designed can exhibit a very low thermal

resistance. Liquid heat sinks can be constructed by soldering copper tubing

on to a flat copper plate or by drilling holes in a metal block through

which water may pass. With greater complexity and greater thermal performance

an elaborate serpentine water channel may be milled in a copper or aluminum

block that later is sealed off. While liquid cooling may be considered

undesirable and /or unsatisfactory for many applications it may be the only

viable approach in specific situations. Liquid cooling, in addition to being

compact, keeps noise to a minimum and can increase semiconductor life due to

reduced temperatures. We can also provide chiller units for complete cooling systems.

Liquid cooled heat sinks provide the highest thermal performance

per unit volume and when optimally designed can exhibit a very low thermal

resistance. Liquid heat sinks can be constructed by soldering copper tubing

on to a flat copper plate or by drilling holes in a metal block through

which water may pass. With greater complexity and greater thermal performance

an elaborate serpentine water channel may be milled in a copper or aluminum

block that later is sealed off. While liquid cooling may be considered

undesirable and /or unsatisfactory for many applications it may be the only

viable approach in specific situations. Liquid cooling, in addition to being

compact, keeps noise to a minimum and can increase semiconductor life due to

reduced temperatures. We can also provide chiller units for complete cooling systems.

For maximum power heat transfer we offer Powder Type heat pipes. These come in standard lengths from 150 to 300 mm. Tube diameters range from 2 to 8 mm with maximum power capacity of 45 watts.

For maximum power heat transfer we offer Powder Type heat pipes. These come in standard lengths from 150 to 300 mm. Tube diameters range from 2 to 8 mm with maximum power capacity of 45 watts.

Typically it is advantageous to design a heat sink

assembly that can reduce waste created by additional handling through

secondary operations at your facility. We will work with you to design

an assembly which can drop right into your product, reducing handling

cost and potential damage. Items integrated into our heat sink assemblies

include, Shielding such as EMI/RFI barrier walls, Hardware like standoffs

and studs for mounting, Chassis and interface sheet metal. Also, we can

provide you with an extensive variety of finishes which include plating,

painting, and silk screening. We want to incorporate as much into the

assemblies as possible so that when you take our assembly to the factory

floor you can immediately interface it to the product for fast shipment

to your customer. We will work with you on mechanical components in order

to reduce your assembly time and inventory cost.

Typically it is advantageous to design a heat sink

assembly that can reduce waste created by additional handling through

secondary operations at your facility. We will work with you to design

an assembly which can drop right into your product, reducing handling

cost and potential damage. Items integrated into our heat sink assemblies

include, Shielding such as EMI/RFI barrier walls, Hardware like standoffs

and studs for mounting, Chassis and interface sheet metal. Also, we can

provide you with an extensive variety of finishes which include plating,

painting, and silk screening. We want to incorporate as much into the

assemblies as possible so that when you take our assembly to the factory

floor you can immediately interface it to the product for fast shipment

to your customer. We will work with you on mechanical components in order

to reduce your assembly time and inventory cost.